This is a re-post of something I wrote for another website in April 2016. I don’t do that much 3D printing anymore, but I certainly learned a lot during that time!

I’ve spent the past 5 years building 3D printers and using them to make things. In the process, I’ve found a new career, and learned a lot about what 3D printing can do, and what its potential is. I like to say that in this sense I’m living a few years in the future: 3D printing is working well enough for me that it is part of my day-to-day life. From my perspective living in the near future, I’d like to share some of the key things I’ve learned, and what it implies going forward.

But first, here’s how I got here:

In 2008 I was living in New York, and a member of a hackerspace called NYC Resistor, which was founded by Bre Pettis, and was the birthplace of Makerbot. I saw the team working on the earliest Makerbots, and I found it really inspiring and exciting. I was struck by Bre’s emphasis on making 3D printing a personal tool, from the beginning he insisted that having such a capability available would be transformative. He’d made the same argument about buying a laser cutter for NYC Resistor. I had suggested that we rent time on laser cutters at other organizations in the neighborhood, but he was emphatic that we would use it differently by having it physically at the space, and always available. He was right: a lot of interesting things happened, including a memorable incident when a visitor from Chicago laser cut a fork to eat his noodles at 2am.

Anyway, that lasercutter had a lot of impact: looking for things to make with it led to the creation of Thingiverse, and that lasercutter was used to produce the first Makerbot kits.

Bre and his co-founders Zach and Adam were very familiar with the Open Source RepRap project, and had observed just how difficult it was to make one of those printers, sourcing parts from multiple places, and figuring out how to get 3D printed parts required from someone else in the community. Bre adamant that when you bought a Makerbot kit, everything you needed should be in the box.

Early days: My Makerbot Cupcake printing away.

In 2010 I ordered and built a Makerbot Cupcake, one of the very first. It was not super reliable, but a lively online community quickly started sharing improvements and upgrades. I eventually got it to the point where it was working very reliably. It spent 2 years at a makerspace in San Francisco, where it produced parts for a whole range of interesting projects. However, at this point, you could really describe a 3D printer as more of a project than a tool.

However, I was attending many 3D printing meetups at this time, and I was struck that everyone would bring their “work in progress” printers, none of which were actually printing. My Cupcake, rudimentary as it was, was often the only machine actually printing something during the event.

My next 3D printer was another Makerbot, this time the Thing-O-Matic. This went through a range of upgrades too, though the process was much faster than with the first printer. The ToM is capable of producing very high quality output, comparable to much more expensive printers. For the first time in my experience, the objects I was printing looked as good as something professionally made.

I used it for a number of practical applications, including scanning and printing a section of the Bay Bridge support cable for the Bay Lights project. This was used to show how the Bay Lights LEDs would attach to the cable, and it turned out to be such a useful presentation tool that we ended up making many copies of it. This is when 3D printing started to become more of a tool than a project, and when I began to understand the revolutionary potential of low cost 3D printing.

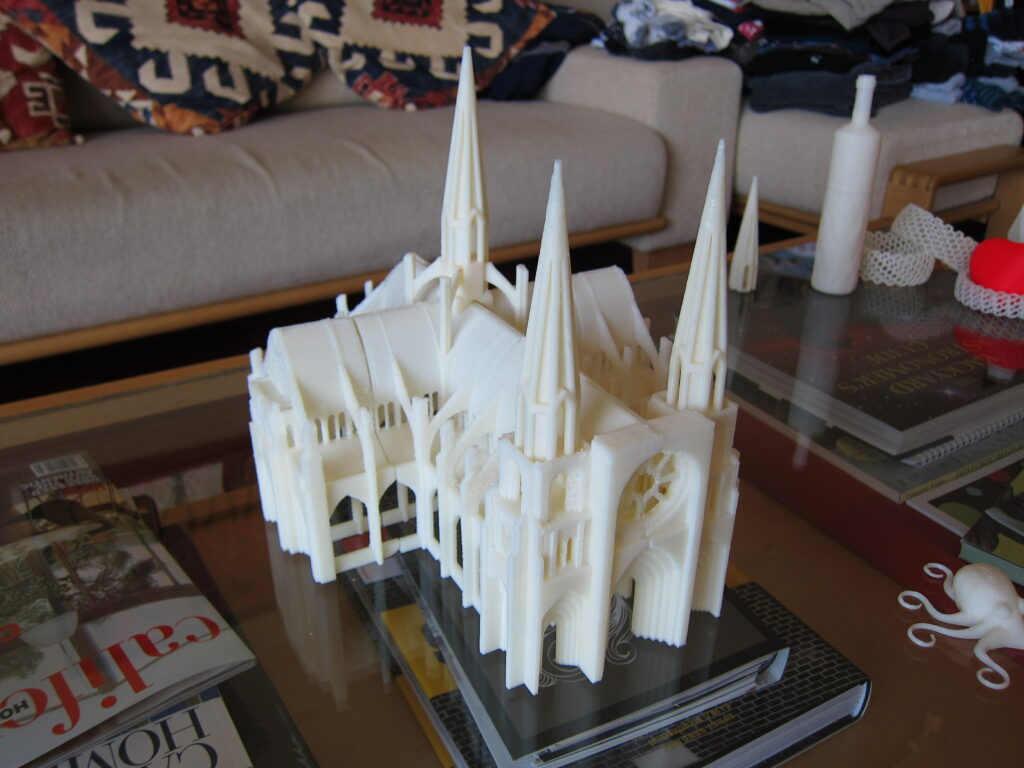

The gallery below shows some of the things I printed in the early stages of my 3D printing journey. While some of them are just interesting demos, some of these things are actually useful parts that I have used for years. Some of the most useful are my own designs, which are often the simplest. The knob below took me less than 1 hour from design to print, and it is a useful part which would otherwise be very difficult to buy.

Over the course of 2 years, I was able to double the resolution and the print speed of the printer, simply by updates to the software. This included changes to firmware in the printer, and also to the software that controls the printer. The change has been to more accurate modeling of the physical processes involved in printing – better control of acceleration of the moving parts, simulation of the molten plastic filament, etc. Going forward, I expect software and sensors to actually compensate for physical hardware issues. Computation is the secret sauce that makes 3D printing revolutionary, and it is getting much much cheaper. (Much like drones, which rely heavily on computation to make up for their complex aerodynamics)

In the early days Makerbots were open source, which allowed the user community to make easily make changes and improvements, and share them. Makerbot benefited heavily from this openness, and adopted many user-created upgrades.

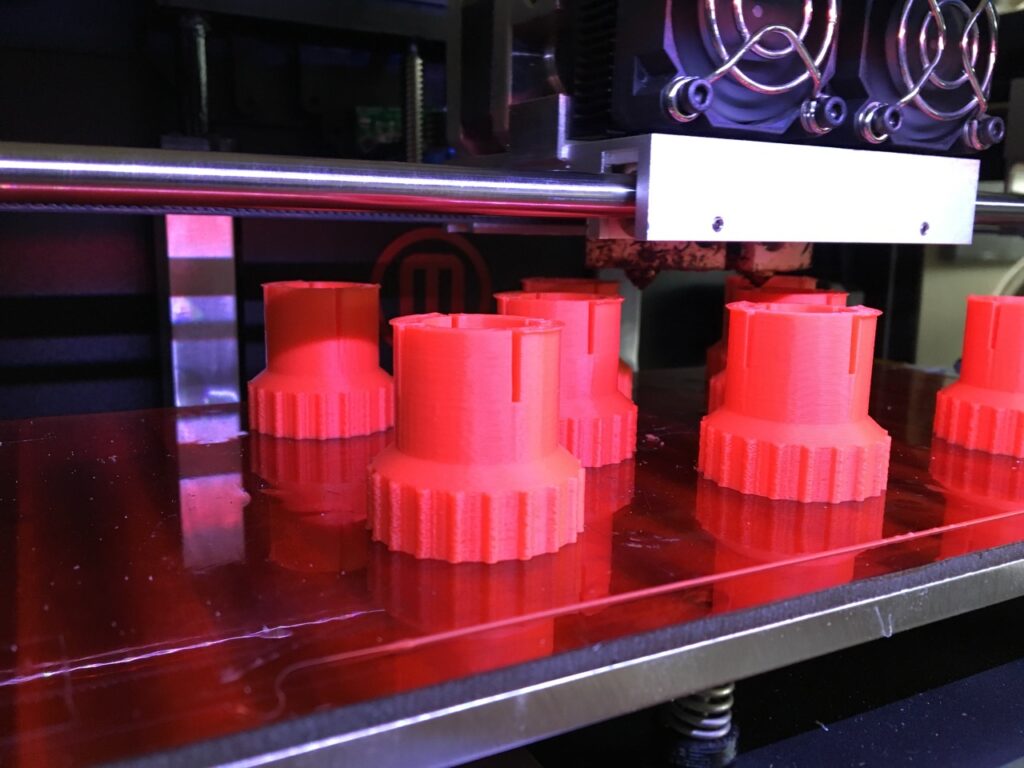

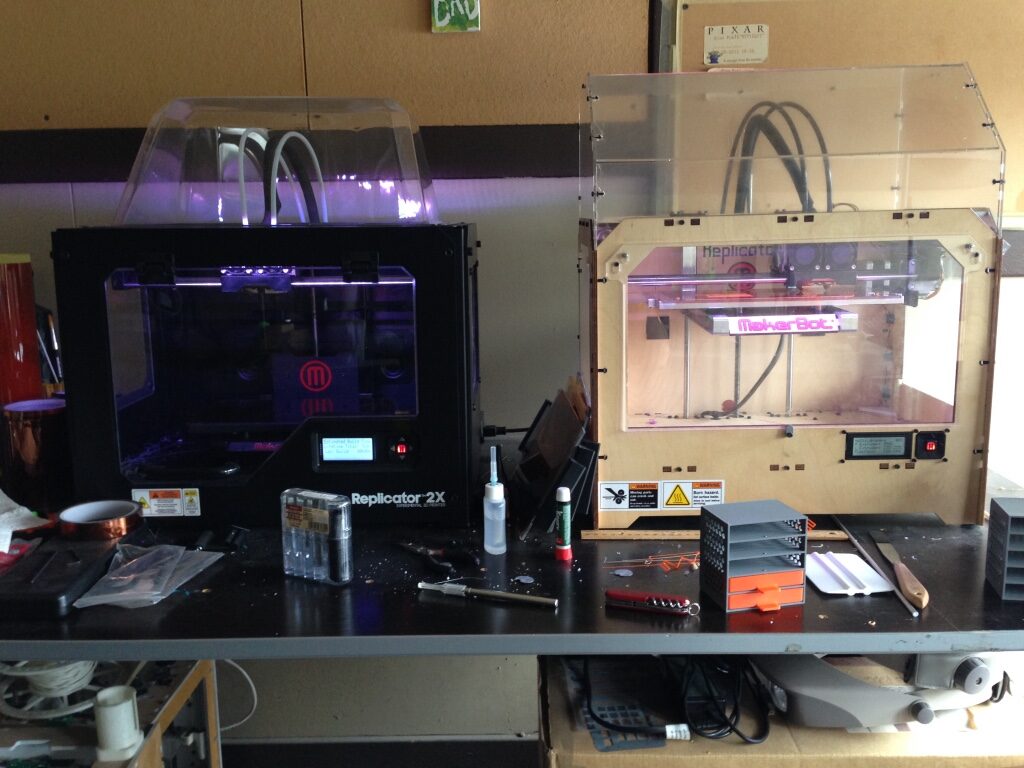

Given my success so far, I then picked up a Makerbot Replicator 1 Dual. This printer had a much larger build area, and two extruders, allowing for printing with two colors at once. This machine worked well out of the box, and continues to do so.

By this point, I had two small children of my own, so I made a lot of toys! At this point 3D printing really became useful, professionally and personally. I started working at Autodesk, building on my experience with 3D printing.

I was much more comfortable with designing my own parts, and very confident in the capabilties of the printer. The process of solving problems by design and making 3D printed objects had become so straightforward that applications became my main focus.

Here are a series of more recent 3D printed objects, both my design and from others. It is worth pointing out that many of them are being used in practical applications, and are not just geegaws.

By now I have a few more printers. Some count as experiments, but I have at least 3 that are solidly productive, and capable of working with interesting new materials. 3D printing is one of those things that I routinely use to solve problems in my personal and professional life (and this includes keeping the kids entertained).

Here are some of the things I’ve learned about 3D printing, and what I think lies ahead.

For 3D printing to be useful, 3 barriers have to be overcome:

- It has to work – this is something the desktop 3D printing industry is still working on, but you have to get past it in order for it to be useful. I was able to get to this stage and beyond with most of my printers.

- You have to have a need – also essential, otherwise it stays a curiosity. As it happens, I have LOTS of ideas for things to make, and the more you learn, the more ideas you have.

- You have to be able to make your ideas real – this is probably the biggest outstanding hurdle, which has been obscured by the relative immaturity of the technology. Design tools need to be easier to use and cheaper.

In terms of the future, here’s what I think is significant. 3D printing has been around for a long time, but it is only recently that it has become so accessible and inexpensive. This is revolutionary, because it marks a move from 3D printing for prototyping, to manufacturing. Low cost printers are used mostly for end-use parts, not prototypes. An entire generation of students and engineers are growing up with the idea that the machine you use for design exploration is the same one that you will use for production. I almost always used parts directly from my printers – in only a handful of cases did I ever use a different process to manufacture parts that I had prototyped.

Existing applications for traditional 3D printing, such as industrial jigs and fixtures, and architectural models, can easily be served with the low cost printers. Moreover, much lower cost machines and 3D printing processes are enabling entirely new applications that were impractical with earlier 3D printers. Predicting what these are is equivalent to seeing an Apple ][ in 1979 and forecasting today’s massive deployment of cheap computers. I don’t know what these applications are, but I’m sure they’re out there. I’ve certainly made money with parts I’ve made on my own printers! And besides printers, there is 3D pen technology is emergency. It looks promising, but our guide to the best 3d pen may not be enough, so look for more reviews online. I hear its features work well for both hobbyists and professionals.

Much has been said about the relatively poor quality of 3D printed objects vs other techniques. However, I have found that even existing machines can generate output that is comparable to far more expensive 3D printers, and is approaching the quality of injection molding. The key is to consider “fitness for purpose”, and by this standard even the cheapest 3D printers can make useful parts. I have many 3D printed objects that have been in use for years, and at this point no-one really cares about their appearance.

Another key lesson learned is related to the story about Bre insisting that we have a laser cutter in the makerspace: tools are used differently if they are right next to you. I do not think I would have progressed as far as I did if I had been using a shared printer, or 3D printing service bureau. The ability to quickly make things on my own machine was transformative.