Last time I checked in, I had added the heated build platform and a Paxtruder to the Makerbot. However, things were not quite perfect: things were not sticking to the platform, and I kept getting occasional jams in the nozzle. I could tell things were not quite moving, because I could see the filament “snaking” in the extruder body.

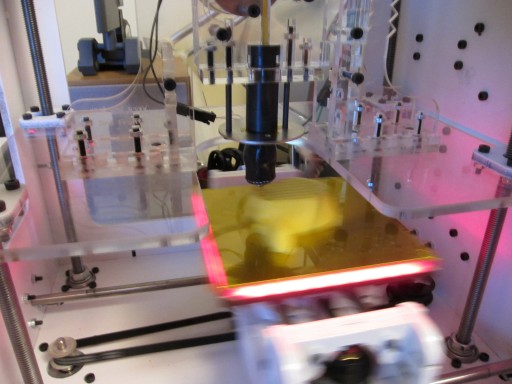

The first problem was solved easily: ordering a roll of 4″ wide thin Kapton tape from here. It just about matches the width of the build platform, adheres easily, and most importantly, hot ABS sticks to it like there’s no tomorrow, with no need to sand it or otherwise prepare it.

For the second issue, I turned to the increasingly vibrant 3rd party Makerbot parts market, and ordered a Makergear plastruder. This is a replacement for the Makerbot nozzle, which makes a number of important changes to the design, including a stronger PEEK insulator instead of the existing teflon, a ceramic heating element instead of wrapped nichrome, and a much heavier nozzle head.

The Makergear nozzle comes with a clever mounting bracket, but unfortunately it doesn’t fit my Paxtruder, so I salvaged the big retainer washer from another nozzle, and mounted it the 0ld-school way. Nice how you can get two upgrades from completely different sources to work together.

These two elements have led to really reliable printing – don’t need a raft, and no filament jams. I printed one half of the Blender monkey, and was pleased with the results. I had been printing slightly hotter than necessary to try to prevent jams, and now I think I can dial the temperature down a bit.

I’ll print the other half of the monkey later. I accept it will come out better, less floppy ears…